10 Mistakes to Avoid when Installing Electric Fences

- Share

- Issue Time

- Dec 6,2021

Summary

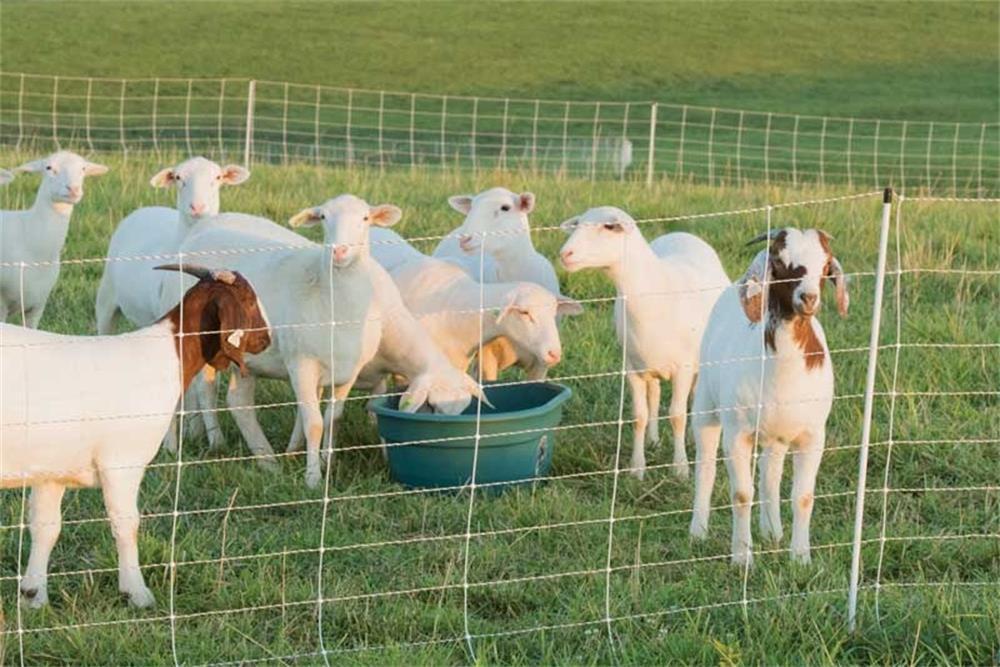

If the electric fence is improperly operated during installation, it will bring a lot of trouble to the subsequent use. Today, let’s talk about the wrong operations that need to be avoided when installing electric fences.

If the electric fence is installed properly, it can play a very good barrier effect and effectively protect our nomadic property. However, if the following wrong operations occur during the installation of the electric fence, it is very likely that the fence will lose its proper function.

Poor earth grounding

What we must all learn to do, is install several ground rods -- at least three that are 6 to 8 feet long, galvanized and attached with good ground clamps. The electricity must complete a full circle back to the charger through the ground. Poor grounding gives weak shocks.

Using different types of metals

Don't do it. When you hook up steel wire to copper something call electrolysis happens and the metal becomes corroded, making a poor contact and weakening shocking power.

Inadequate animal training

Each and every animal must learn that the fence will hurt them. So please build a handy training fence, preferably on heavy wet soil. Flag the fence for visibility, and force the animal to try and cross the fence.

Fence posts are too close

If the fence posts are only 50 feet apart on flat ground, they are too close. When something hits the wire, you shouldn’t want to break all the insulators or knock the pillar out of the ground. If the posts are separated far enough—say 80 to 100 feet—the wires will bend to the ground and bounce back.

Too many wire tie-offs

Again, fencing specifications may call for braces every quarter mile wire to tie the wire off. Even 5,000 feet is proper, and it actually adds more elasticity to the fence wire. This reduces the chance of wires breaking.

Building new fences near old existing fences

Old fence wires seem to be always moving somewhere and coming in contact with the new electrified wires. This almost always causes a complete short in the fence, and away the animals go.

Bottom wire in contact with heavy, wet vegetation

Wet grass can make electric fence charger touch water and may cause it to malfunction. Hook up the lower wires separate from the other wires, and install a switch for the lower wires that you can turn off when the grass is tall.

Poor-quality insulators

Be careful here. Sunlight deteriorates plastic, so you need to buy good-quality, long-lasting insulators. Usually, black ones are treated to resist degradation by ultraviolet light. Poor-quality insulators turn white or clear after a few years in direct sunlight.

Kinks in high-tensile wire

A small kink in the stiff wire will always break. We also avoid hitting this kind of wire with a hammer, as this will easily damage the wire causing a break. We always cut out a damaged section of high tensile wire and splice it. Incidentally, a hand-tied square knot makes the strongest splice.

Installing in-line strainers close together

Wires will flip together once in a while. If in-line strainers are installed one above the other, they will sometimes hook up. Separate in-line strainers by a fence post and they will never catch on each other.

In addition, when we choose the electric fence charger, we should pay attention to choosing low impedance, from a reliable supplier, and with a warranty and replaceable components. If you want to know more about electric fences after reading the above, you can get a comprehensive solution by contacting us.

With excellent R&D technology and thoughtful service, we have become one of the leading manufacturers of electric fence products. We have a professional production team and strict quality inspection system, which can carry out all-around quality control on the quality of products. At the same time, we will also provide thoughtful one-stop service according to the diverse needs of customers. If you are interested in our electric fence, please contact us immediately!